FUEL SYSTEM

I have departed from the norm and designed my own fuel delivery system.

There has been a lot of reported leaks at the fittings at the tank.The reason I believe these leaks are happening is because the shut off valve is directly connected to the fitting at the tank and repeated on ,off motions of turning the valve is applying an offsetting movement to the fitting which in my opinion will eventually cause a leak.It's like giving the fitting a little wiggle over and over.The more often you fly the quicker the leak.I am sure those that have escaped the leaks have worked out through design or by luck to limit or eliminate this movement .

As always, take my opinions as you wish.Copy my method or don't.

This will require a centre panel of some sort to house the shut off .Mine also houses the fuse block and the cabin heat pull and my Grand Rapids Engine Monitor, so it came in handy.

So I decided to eliminate any movement at the fitting completely.

Cost a little bit more but I think it is money well spent if I never have to take everything apart to replace the fitting

down the road.

Sonex's latest answer is to replace there smaller fitting with there oop,s fitting from the get go.While I think the larger fitting will be somewhat more robust ,time will tell if it will survive repeated on/off cycles.

You decide for yourself.

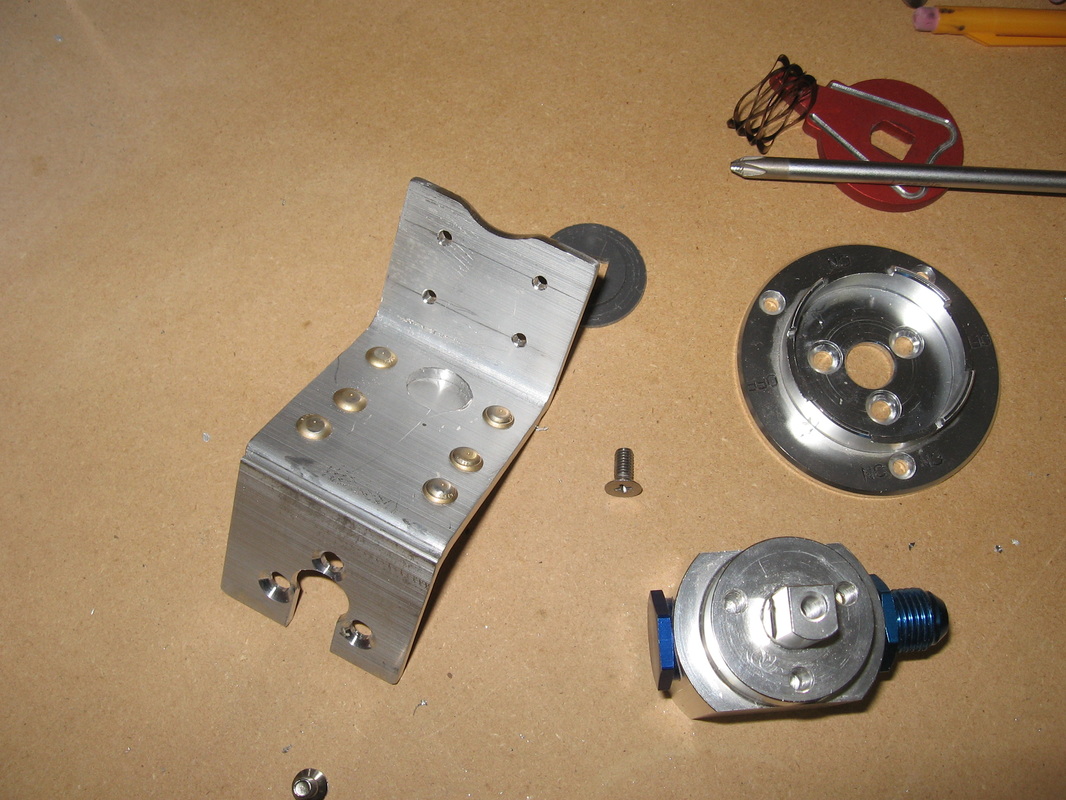

This is the shut off valve I bought.

http://www.aircraftspruce.ca/pages/ep/fuelvalve_newton/fuelvalvessprlv2.php

There has been a lot of reported leaks at the fittings at the tank.The reason I believe these leaks are happening is because the shut off valve is directly connected to the fitting at the tank and repeated on ,off motions of turning the valve is applying an offsetting movement to the fitting which in my opinion will eventually cause a leak.It's like giving the fitting a little wiggle over and over.The more often you fly the quicker the leak.I am sure those that have escaped the leaks have worked out through design or by luck to limit or eliminate this movement .

As always, take my opinions as you wish.Copy my method or don't.

This will require a centre panel of some sort to house the shut off .Mine also houses the fuse block and the cabin heat pull and my Grand Rapids Engine Monitor, so it came in handy.

So I decided to eliminate any movement at the fitting completely.

Cost a little bit more but I think it is money well spent if I never have to take everything apart to replace the fitting

down the road.

Sonex's latest answer is to replace there smaller fitting with there oop,s fitting from the get go.While I think the larger fitting will be somewhat more robust ,time will tell if it will survive repeated on/off cycles.

You decide for yourself.

This is the shut off valve I bought.

http://www.aircraftspruce.ca/pages/ep/fuelvalve_newton/fuelvalvessprlv2.php

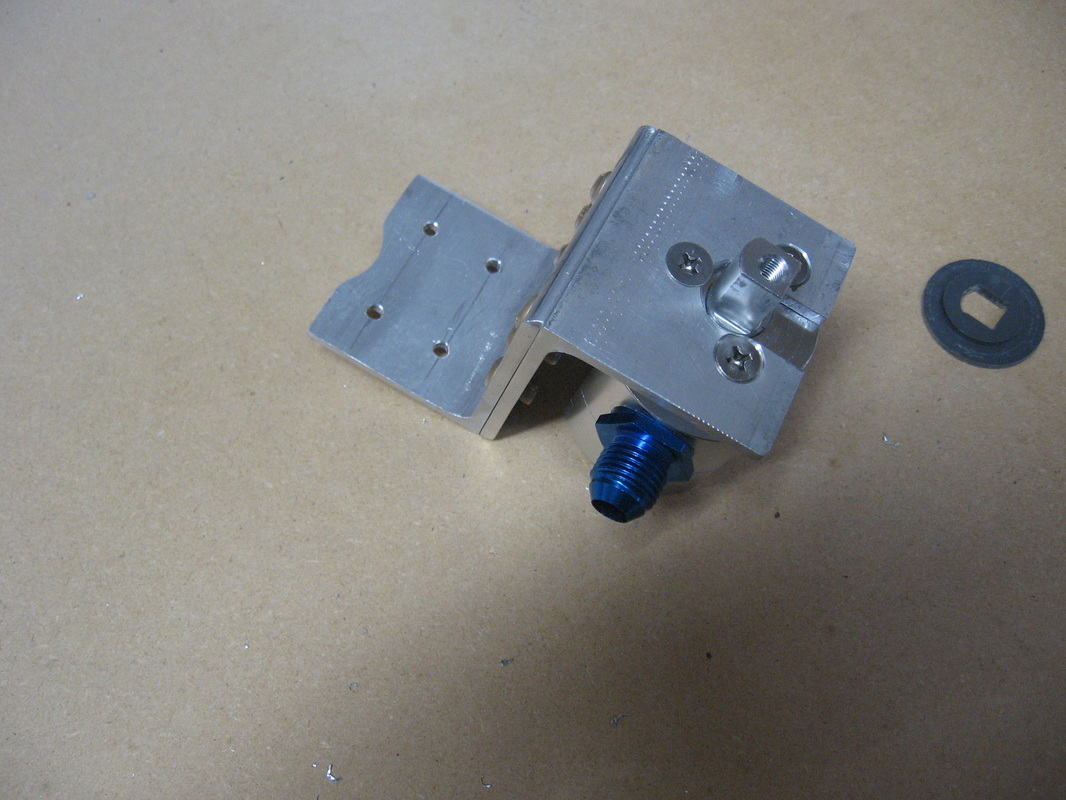

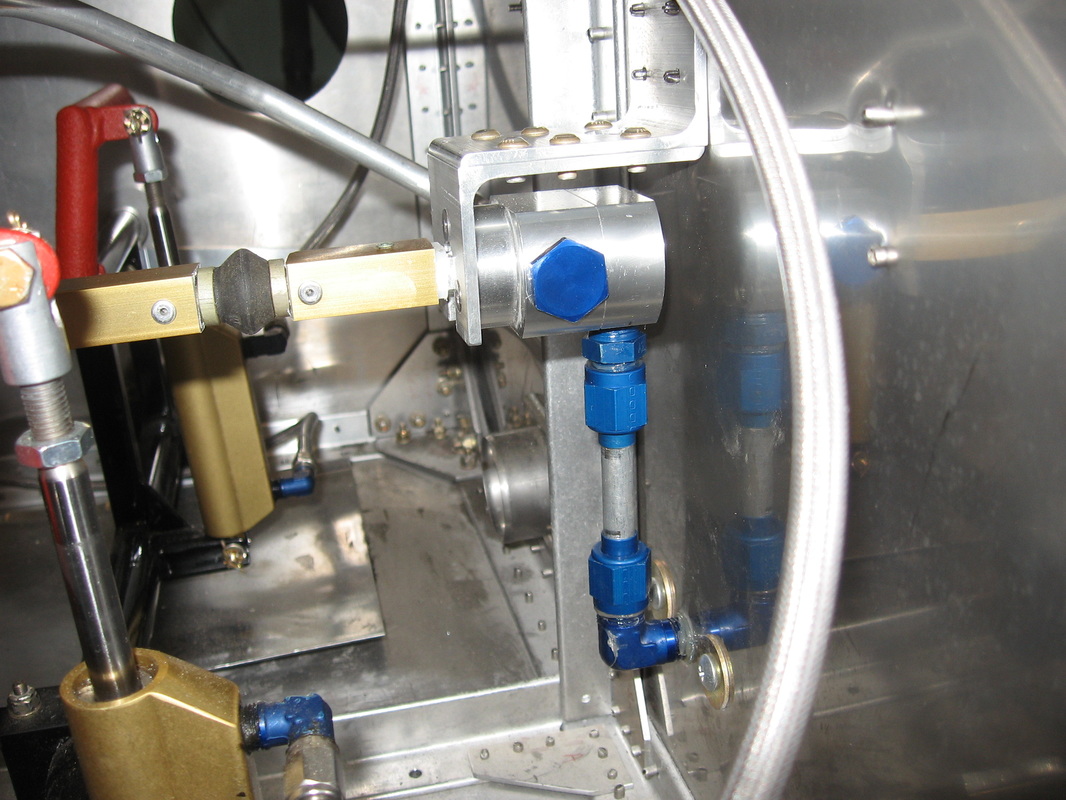

Newton doesn't have any type of bracket or built in method of attaching the valve to the firewall,so I made my own.

I made it so that it can easily slip out once the three screws are removed.The three screws are what held the face on to the valve so I simply copied the pattern onto my L bracket.

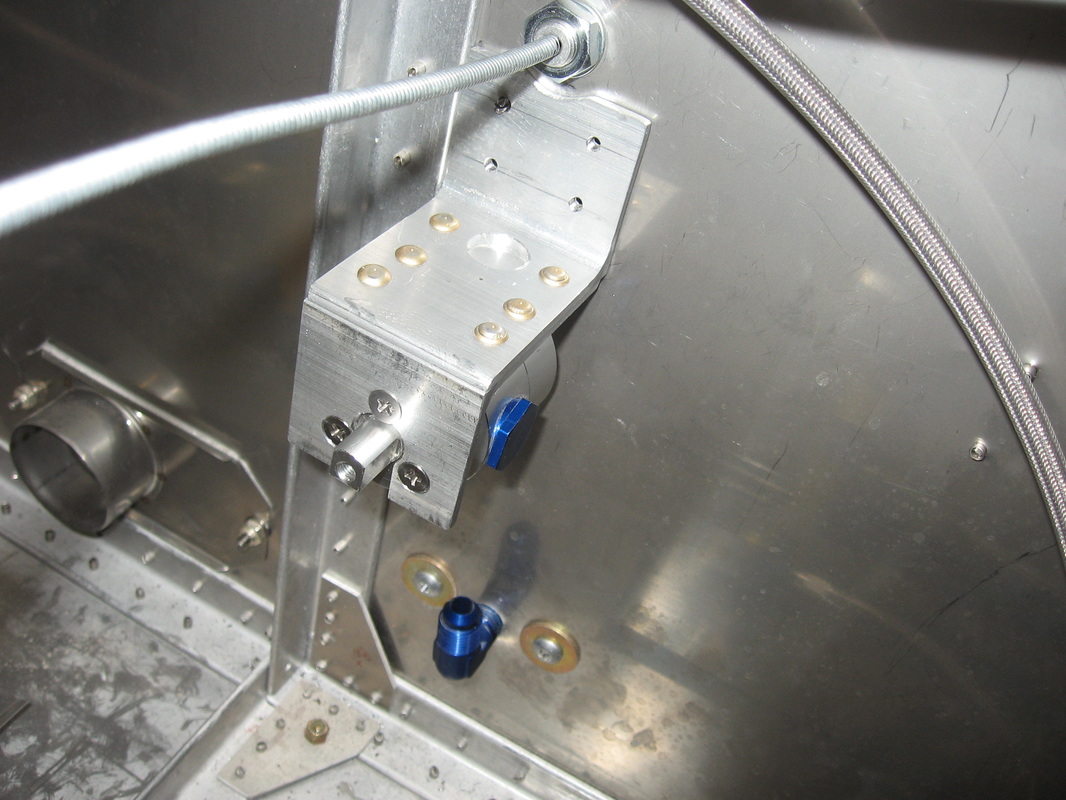

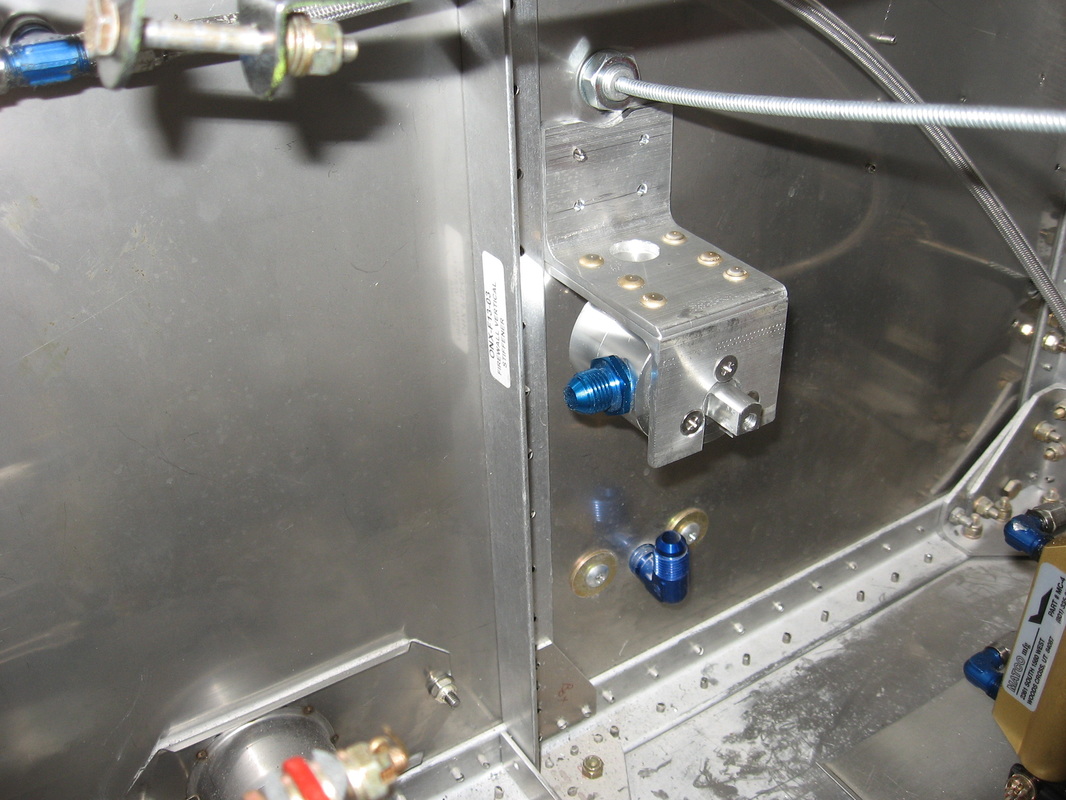

Getting attached just above the Gascolator.This is where the turning movement will take place .No where near the gas tank fitting.

From this angle you can see where the fuel line from the tank will enter.

To the left and about middle you can see the gas tank fitting and how the fuel line will go downhill to the fitting on the side of the valve.Again it can be seen that there will be no movement at the gas tank fitting,just a simple draining of the tank into the fuel valve and then down through the gascolator.

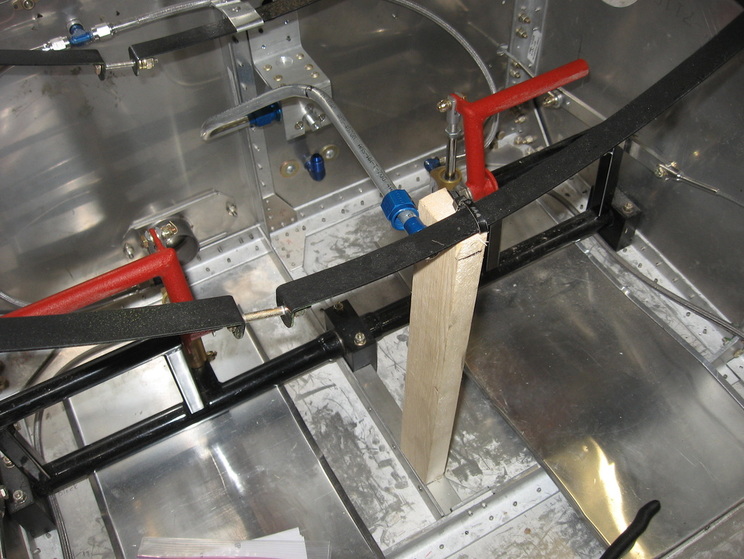

On order from A.S. is an extension that will fit into the on-off face that will be on the other side of that centre panel.I am using the wooden dowel to figure out what length to cut the valve extension.

I am still waiting for the extension to arrive.

Later.

I am still waiting for the extension to arrive.

Later.

Installed a fuel line from tank to fuel valve

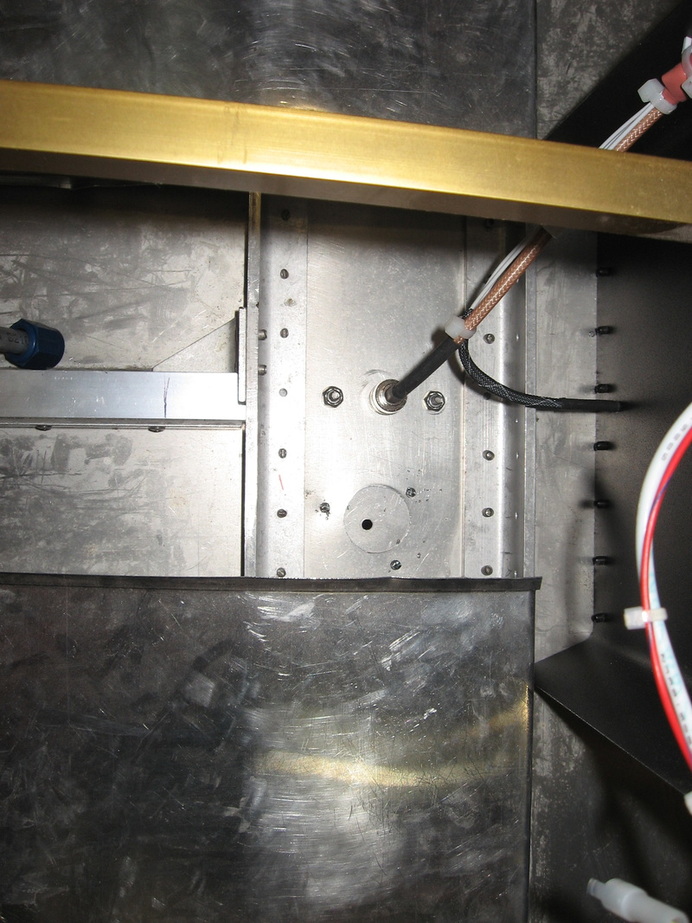

Sonex recommends that you cut 2" off the top of the probe to facilitate removing it from the tank as it is too long .The probe is not too long for the tank.

Instead I cut a 1 1/8" hole and made a plate to cover it,held by 3 self tapping screws.

If the probe ever needs replacing I will remove the plate covering the hole and the probe will pass through the hole

Instead I cut a 1 1/8" hole and made a plate to cover it,held by 3 self tapping screws.

If the probe ever needs replacing I will remove the plate covering the hole and the probe will pass through the hole